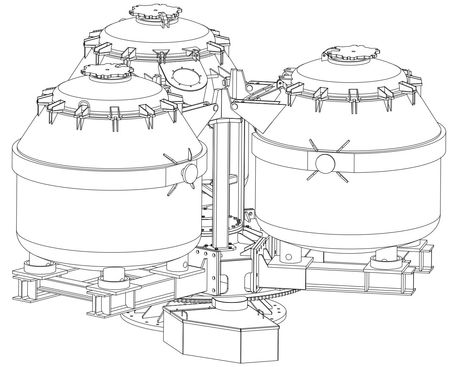

The rotary crucible mount is used for filling aluminium transport containers with a capacity of 5 to 6 tonnes. A total of three crucibles can be placed on the rotating plate simultaneously. When using standard casting channels positioned approximately 680mm above the foundry floor, a crucible pit measuring approximately 2,400mm below floor level will be required. The empty crucibles are placed in the foot mounts on the rotating plate and rotated into position below the casting channel running from the holding furnace.

The filling process can then be started. The built-in weighing system makes it possible to monitor and control the filing process. Once the first container is full, the flow of material is briefly interrupted and the rotary crucible mount is moved forwards by one position. The next empty container is now in the filling position, while the filled container can be scraped down and sealed. The crucible is then lifted out of the rotary mount using a crane and lifting beam and replaced with a new, pre-heated, empty container. The rotary movement of the crucible mount is electronically blocked during filling.

As an optional extra, it is also possible to adapt an impeller system for use on the rotary crucible mount in order to introduce gas to the melt inside the transport container, thus improving the hydrogen content and the quality of the melt immediately prior to delivery.

Specifications

- Base frame with built-in load cells

- Buckling-resistant base frame

- Replaceable load cells for measuring the fill

- Rotating frame

- 1.5 kW gear motor

- Slewing ring with spur gears

- Rotating frame with container foot mounts

- Mechanical blocking system

- Catwalk

- Includes staircase and railings

- Diamond plate floor

- Perimeter railing with knee and foot rails

- Pit lining

- Robust 1.10 m protective railing made of 114 mm circular tubing with knee rails

- Opening in railing for access to the foundation pit and the channel system